CAST STUDY

Inkbit Technology Enabling a Watertight Solution for Hydrific, Through Makelab

Hydrific, backed by global leader LIXIL, is at the forefront of innovation in the dynamic field of water conservation and sustainability. Focused on making water conservation accessible and enjoyable, Hydrific launched of its first product, Droplet. Droplet is a Smart Home loT product that gives homeowners and tenants high-resolution water data and insights.

Challenge

Hydrific’s Prototyping Dilemma: Crafting Precise, Watertight Seals for the Innovative Droplet Device

The primary challenge faced by Hydrific was to develop seals and gaskets for the Droplet that were not only exact in dimensions but also ensured complete watertight integrity. Traditional 3D printing methods and materials could not meet these specific demands, posing a significant hurdle in the development process. The Hydrific team had previously experimented with silicone-like printing materials and other flexible SLA materials but found them too thick for their requirements. Soft tooling was another option, but it was slow and costly. Hydrific was looking for a faster, more costeffective solution to meet their high-quality standards.

Solution

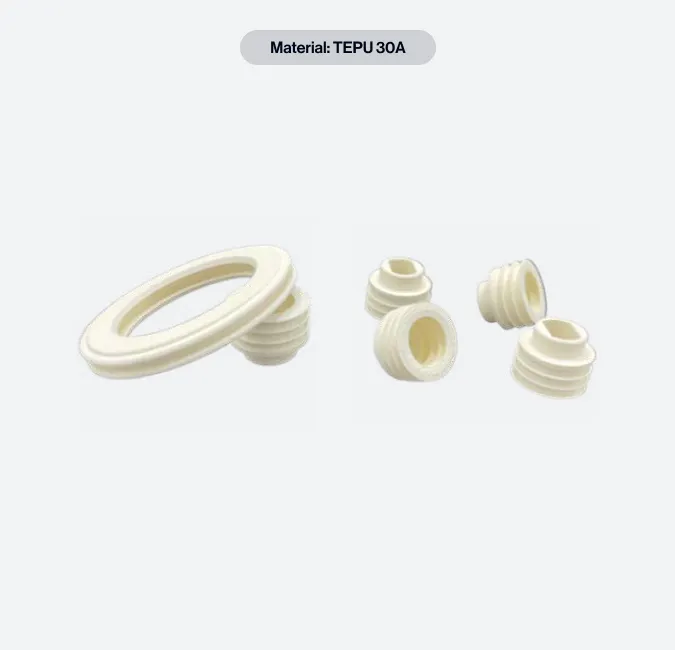

Inkbit’s TEPU 30A Material Resolves Hydrific’s Prototyping Challenges

The breakthrough came with the discovery of Inkbit’s TEPU 30A material, a thin and flexible solution that met all the requirements for Hydrific’s prototype. This material enabled the creation of precise, cost-effective, and rapid prototypes essential for field testing. Makelab played a crucial role in this phase, providing their printing support and expertise, which was vital in effectively utilizing Inkbit’s innovative material.

“It is gamechanging to have something this thin, flexible, and functional. I didn’t know this was possible. I can imagine the incredible potential of this new material for testing asymmetrical and complex seal designs for various applications. The TEPU material and Vision Controlled Jetting technology can extend beyond seals and gaskets to applications like flexible hinges, over-molded parts, and even wearables.”

| Emilie Williams, Industrial Designer and co-founder of Hydrific

Key Takeaways

Inkbit and Makelab’s Collaboration Drives Success for Hydrific, Paving the Way for Future Innovations in Water Conservation

This successful partnership between Hydrific, Inkbit, and Makelab signifies a significant advancement in water conservation technology. Integrating Inkbit’s 3D printing technology and Makelab’s 3D printing services has facilitated the successful development of components for Hydrific’s Droplet and supports Hydrific’s significant strides in water conservation.