Additive Manufacturing Production System

Powered by VCJ

Inkbit Vista™ Unlocks Additive Manufacturing at Production Scale

HIGH-VOLUME PRODUCTION

DIMENSIONAL ACCURACY

FUNCTIONAL MATERIALS

LOW-LABOR

POST-PROCESSING

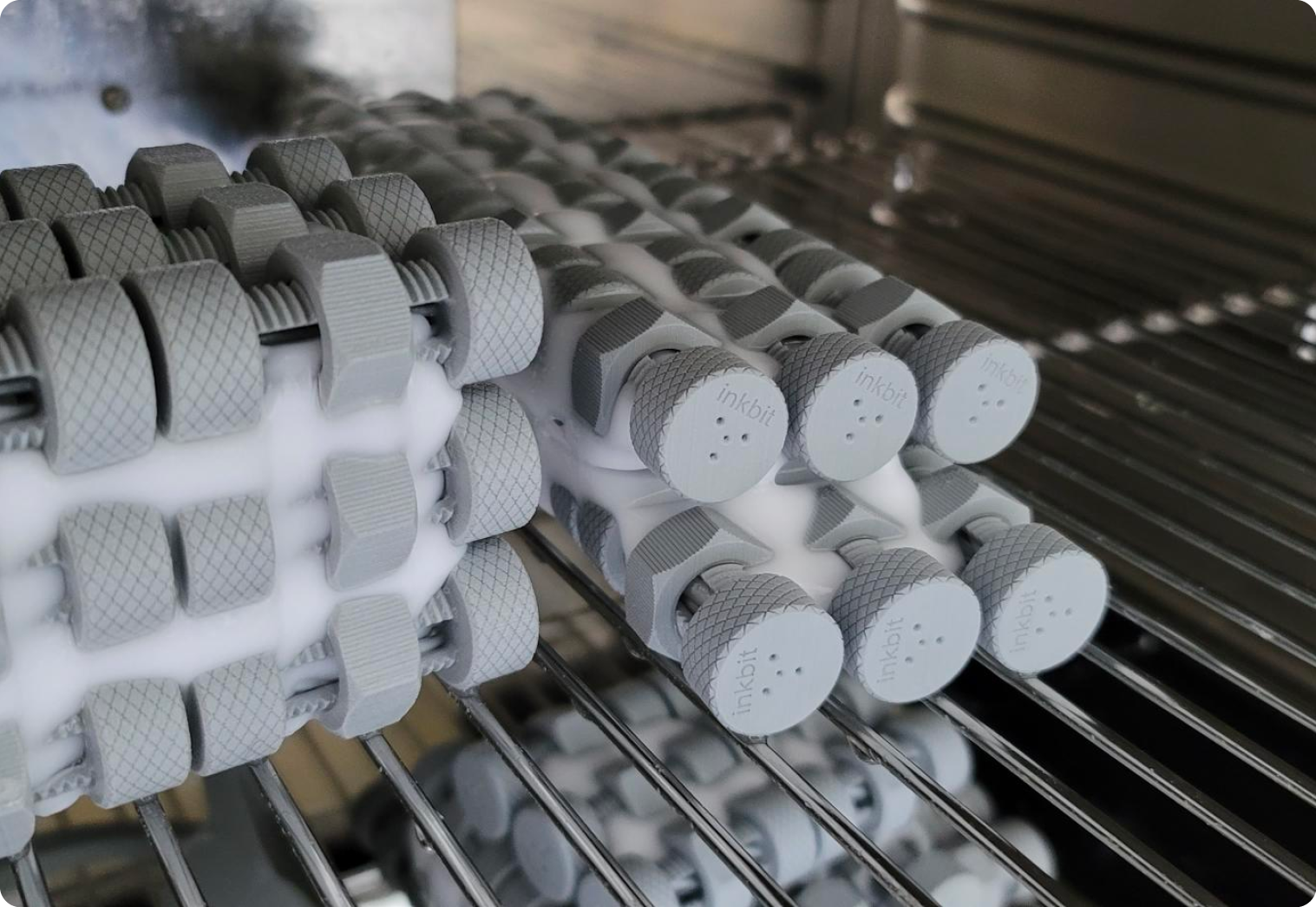

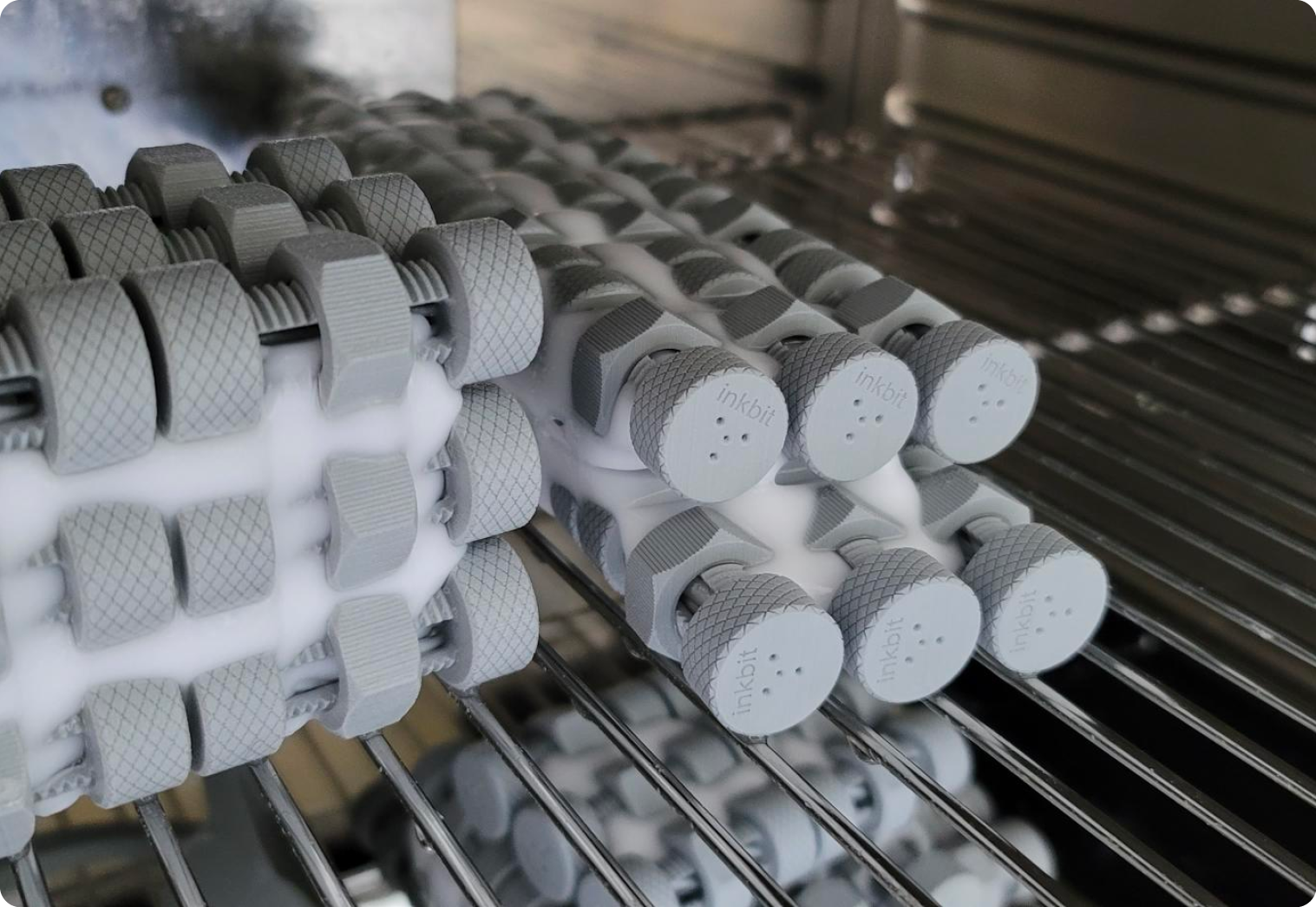

High-Volume Production

Inkbit architecture and integrated VCJ technology allow scaling to high production volumes.

High-Volume Production

Inkbit architecture and integrated VCJ technology allow scaling to high production volumes.

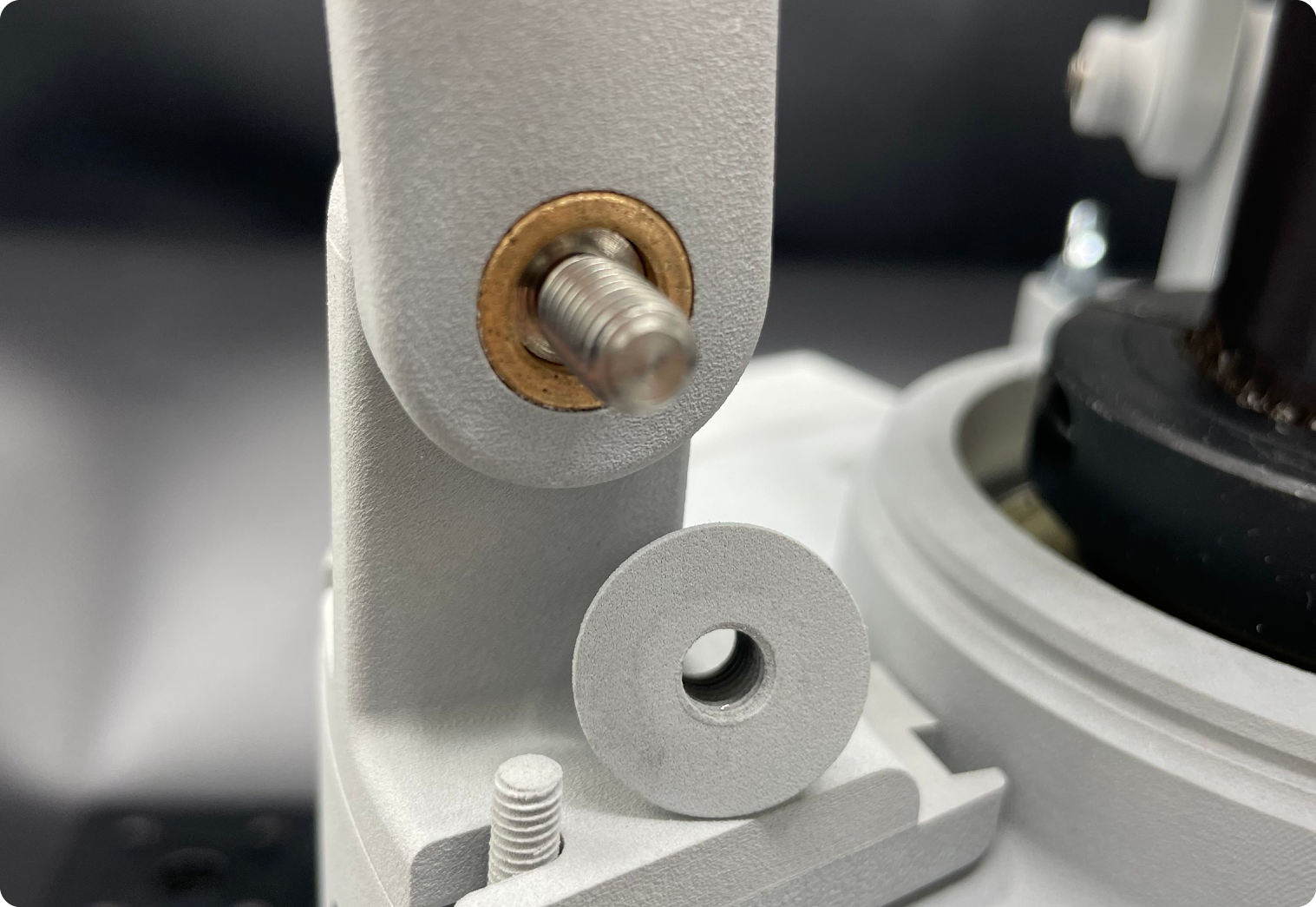

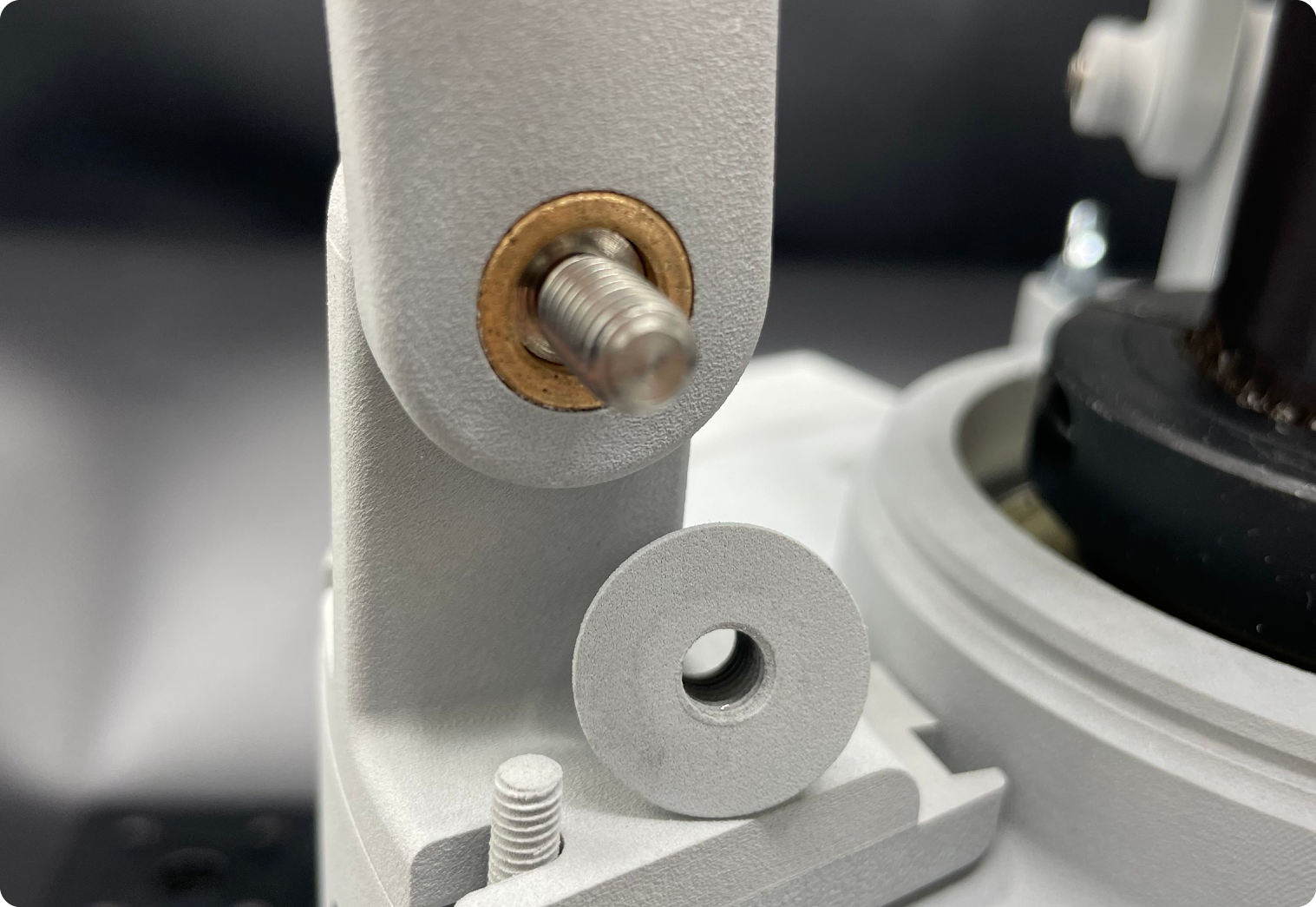

Dimensional Accuracy

Closed-loop feedback control ensures that parts are consistently accurate to the original CAD design.

Dimensional Accuracy

Closed-loop feedback control ensures that parts are consistently accurate to the original CAD design.

High-Functional Materials

Inkbit’s engineered resins provide robust mechanical, chemical, and thermal properties that remain stable through extended service lives.

High-Functional Materials

Inkbit’s engineered resins provide robust mechanical, chemical, and thermal properties that remain stable through extended service lives.

Low-Labor Post-Processing

Automatable post-process and safe, recyclable support material enable production applications by lowering cost per part.

Low-Labor Post-Processing

Automatable post-process and safe, recyclable support material enable production applications by lowering cost per part.

Inkbit Vista™ Specifications

| Print Engine | Vision-Controlled Jetting (VCJ) |

| Build Volume (X, Y, Z) | 500 mm x 250 mm x 200 mm 19.6 in x 9.8 in x 7.8 in |

| Concurrent Materials | Four (three engineering, one support) |

| Dimensions & Weight | 2.8 m x 1.5 m x 2.4 m Approximately 1,500 kg |