Unlocking Innovation in Every Industry

Empowering designers, engineers, and product managers to directly manufacture entire assemblies.

We have begun transformative collaborations in many industrial applications, from industrial automation, manifold and fluid handling, wearables, and external medical devices to on-demand production.

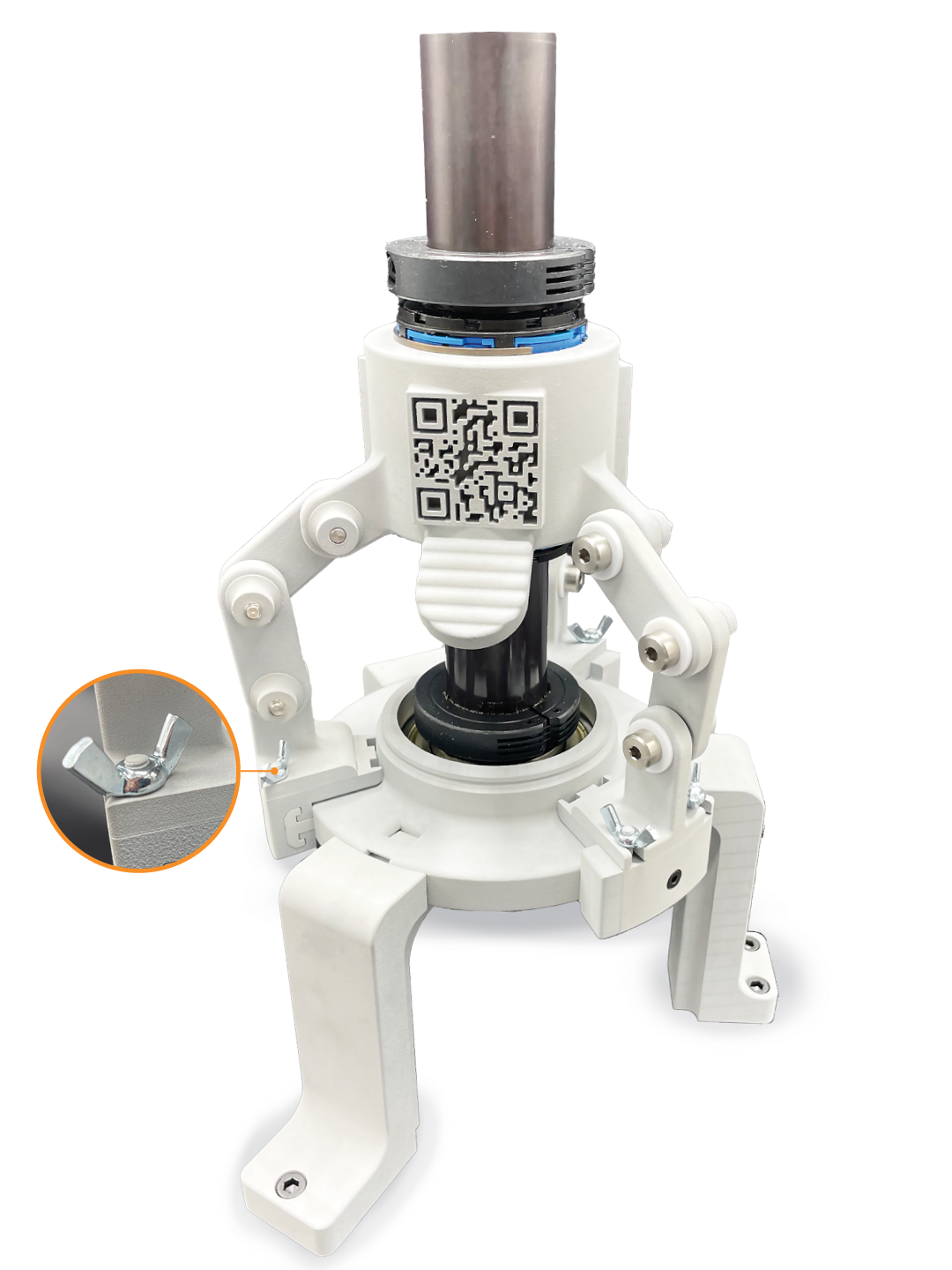

Industrial Automation

Rethink how industrial automation equipment can be designed and manufactured with our Inkbit Vista™ platform. Traditional machined and molded assemblies can be simplified and consolidated for improved performance and reliability.

Material Advantages

- Durable and impact-resistant

- Long-term UV stability

- Integrate fluid/air handling into components

- Consolidate assemblies

- Precise features and tolerances

Manifolds & Fluid Handling

Designing manifolds for fluid handling is complex and has many constraints. The Inkbit Vista™ platform allows the geometric freedom of 3D printing while offering highly chemical-resistant materials with higher endurance than other additive manufacturing solutions.

Material Advantages

- Compatibility with organic solvents

- Resistance to acid/base solutions

- Support easily removed from high aspect ratio channels

- High temperature resistance

- Non-porous, fully dense parts

Wearables and External Medical Devices

Making soft parts? Eliminate injection mold tooling costs and save time on silicone molding by directly printing on the Inkbit Vista™ platform.

Material Advantages

- Very soft and compliant

- Excellent rebound

- High elongation

- Ultra-fine details

- Long-term UV stability

On-Demand Production

Unleash the creativity in you with production-scale additive manufacturing on the Inkbit Vista™ platform. Inkbit Vista™ offers unparalleled production capacity and part quality with fast, hands-free post-processing.

Material Advantages

- Durable and impact-resistant

- Long-term property stability

- Integrate fluid/air handling into components

- Consolidate assemblies

- Precise features and tolerances