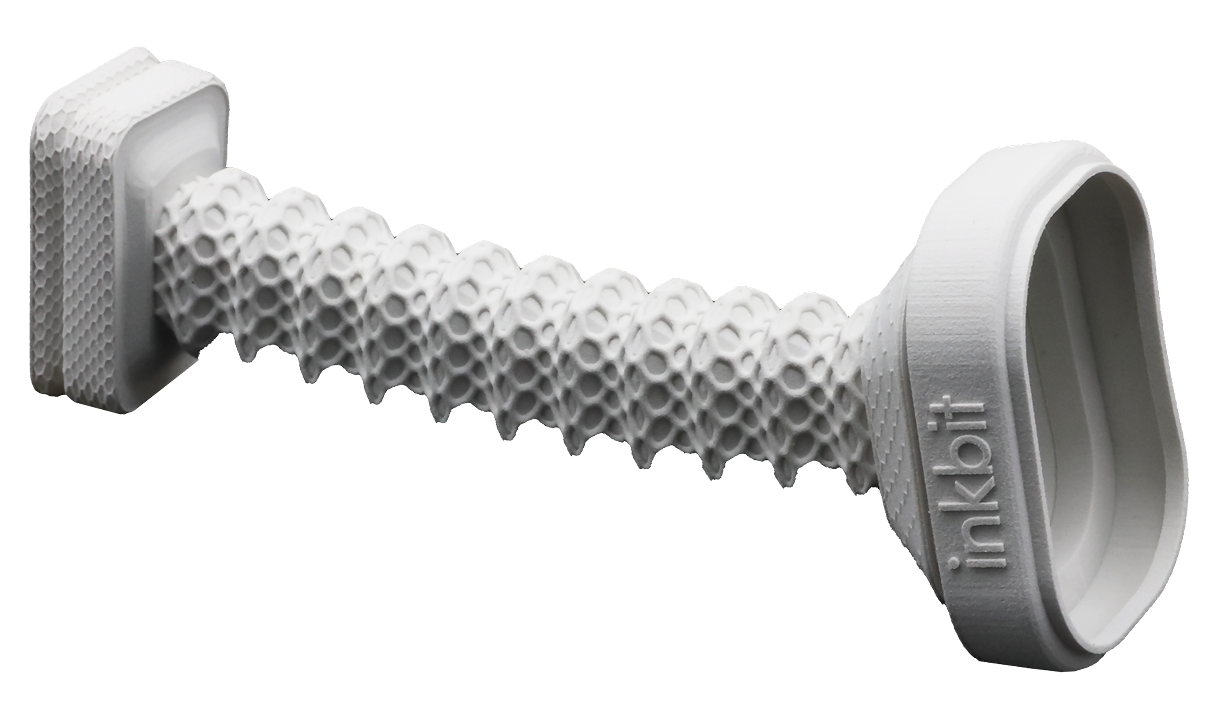

TEPU™ 30A and 50A Elastomers for Prototyping and Production

Inkbit’s 3D printing with our TEPU 30A and 50A materials allows for the prototyping of intricate parts.

In as fast as 5 days, you can prototype complex parts, from seals and gaskets to soft-touch components and durable elastomer prototypes. These materials are suitable for a range of applications such as medical devices, automotive parts, or custom gaskets, providing the necessary flexibility and resilience for diverse manufacturing needs.

Efficient Prototyping with Inkbit Elastomers

Functional Prototyping

The TEPU 30A elastomer is suitable for prototypes demanding softer feel, with shore hardness of 25-25A and high elongation at break up to 200%.

Durable Elastomer

For applications that necessitate a medium softness with resilience, TEPU 50A is an appropriate choice. This material has a low compression set and is resistant to UV and chemicals, making it suitable for creating durable gaskets, grommets, and seals.

Streamlined Production Process

Our 3D printing service facilitates the creation of elastomer parts in as little as 5 days, bypassing the extended timelines and expenses often associated with traditional manufacturing methods.