Why would you want to work with Inkbit?

Fast Turnaround Times

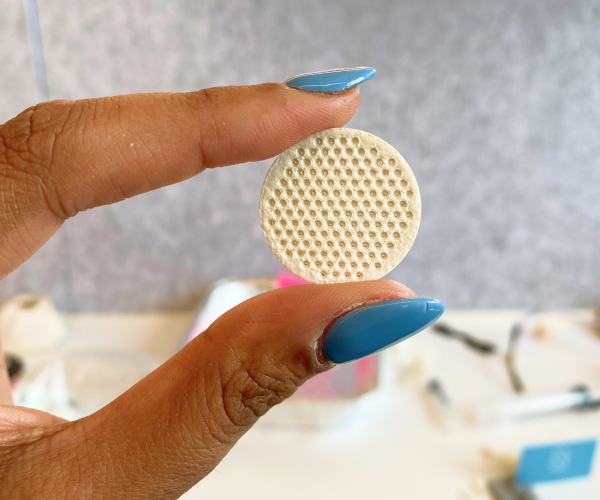

Precision Printing

Our technology is calibrated to capture every detail accurately, enabling the production of designs with high fidelity to the original specifications.

Fast Turnaround Times

Precision Printing

Our technology is calibrated to capture every detail accurately, enabling the production of designs with high fidelity to the original specifications.

Reduced Tooling Costs

Precision Printing

Our technology is calibrated to capture every detail accurately, enabling the production of designs with high fidelity to the original specifications.

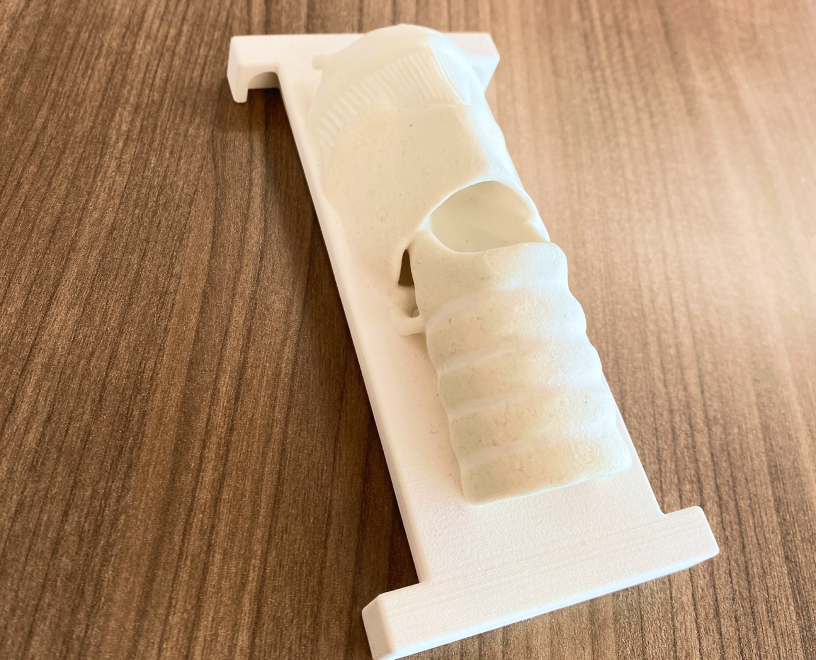

Multi-Material Printing

Precision Printing

Our technology is calibrated to capture every detail accurately, enabling the production of designs with high fidelity to the original specifications.

Why would you want to work with Inkbit?

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliquat enim ad minim veniam. Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

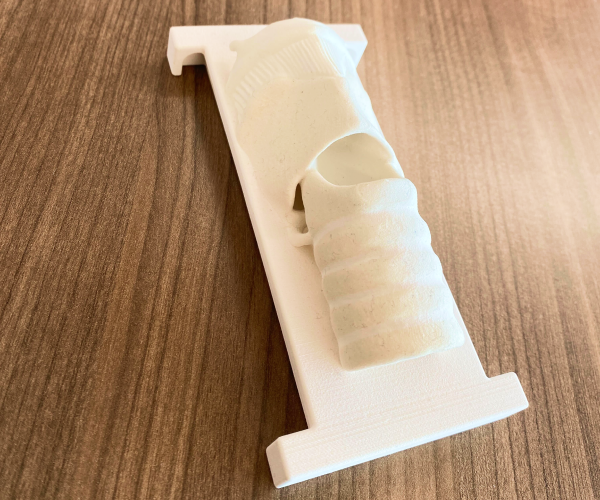

Multi-Material Design Guide

Download the full guide to uncover how to design multi-material parts using functional materials with Inkbit’s VCJ process.

Contact Us