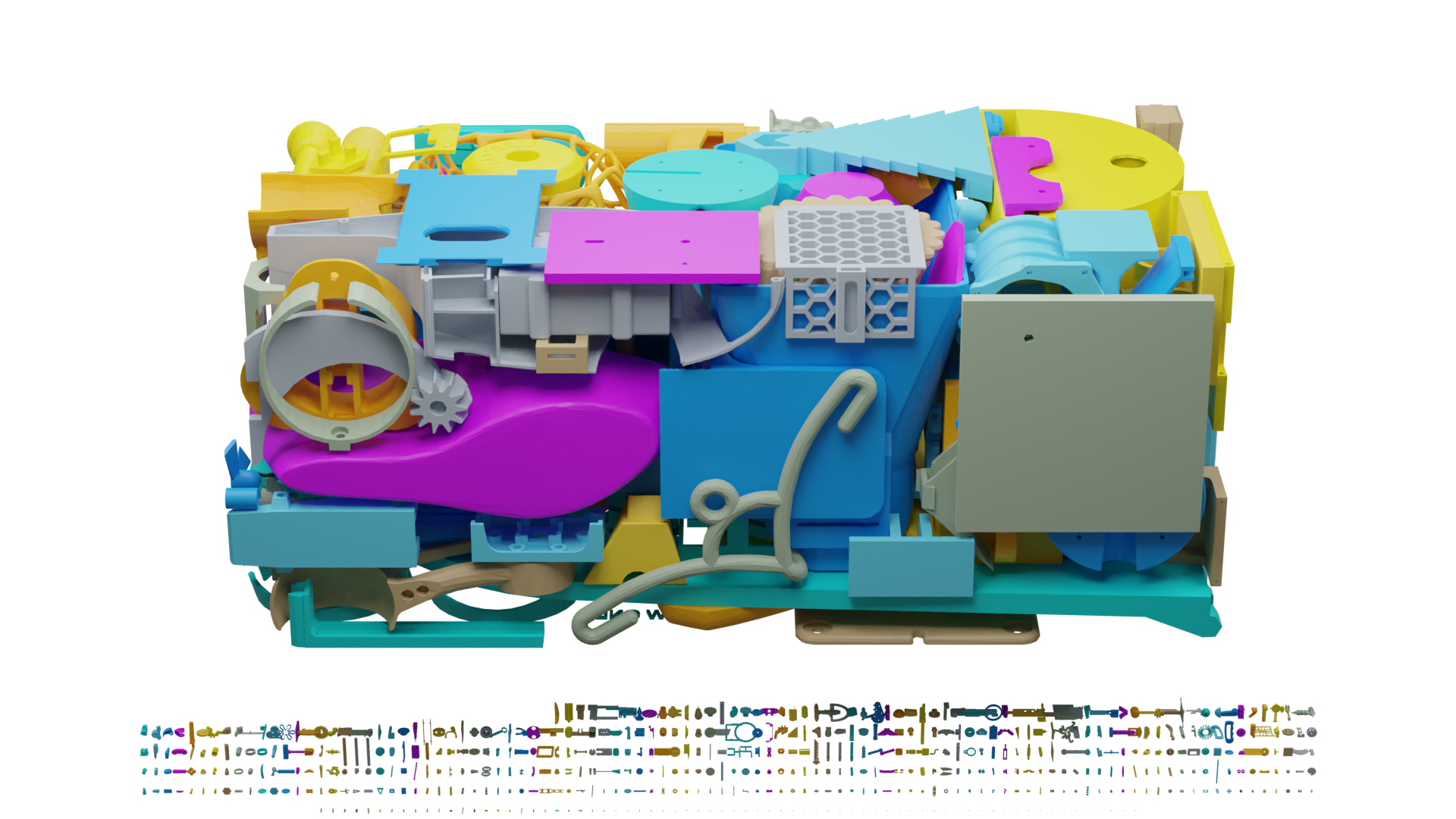

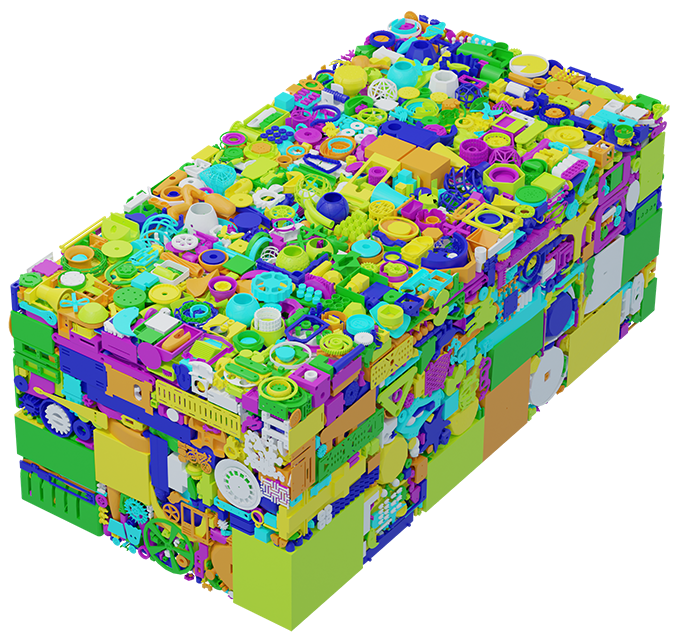

The team of researchers, led by Wojciech Matusik, CTO at Inkbit and professor of electrical engineering and of computer science at MIT, developed a novel computational method to maximize the throughput of 3D printers by packing objects as densely as possible and accounting for interlocking-avoidance (between many parts with different shapes and sizes) and scalability. Their approach leverages the Fast Fourier Transform, or FFT, a powerful algorithm that has made it possible to quickly perform complex signal processing operations that were previously impossible or prohibitively expensive.

Coupled with FFT, “our work is making the individual placement of a 3D part into a partially filled build volume as fast as possible,” says Matusik. “Our algorithms are not only extremely fast but they can now achieve print volumes with much higher densities (40% or more). The higher print efficiency will unlock lower cost of parts manufactured.”

The lead author Qiaodong Cui is set to present the new work at SIGGRAPH 2023. The team also includes Victor Rong of MIT, and Desai Chen, research engineer at Inkbit. Visit the team’s page for the full paper and video.

The Refined Knitting Machine

Some may say that knitting is a relatively easy technique, or craft, to learn — and could even serve as a relaxing stress-reducer. Automating the needle-and-yarn technique with machine knitting is well established in the fashion and textiles industries. This has seen a recent surge in popularity due to increased understanding of the scope and complexity of the objects — fabrics, patterns — that can be automatically generated.

While the technique of knitting has been automated, the systems are still struggling with the ability to support everything that a knitting machine can make, as well as generate precisely what a user wants. To date, say the researchers, there is no such system that guarantees correctness on the complete scope of machine knitting programs.

A multi-institutional team of computer scientists from Carnegie Mellon University, MIT, and University of Washington, have created a novel computational framework to optimize machine knitting tasks. Their formal semantics for the low-level Domain Specific Language used for knitting machines provides a sophisticated definition of correctness on the exponentially large space of knitting machine programs.

The researchers applied knot theory to develop their new framework and addressed the key properties humans care about in knitting that are poorly captured by existing concepts from knot theory. To that end, they devised an extension to knot theory called “fenced tangles” as a mathematical basis for defining machine knit object equivalence.

Our method “can describe anything a knitting machine can make: not just your standard sweaters and hats, but also dense, shaped structures useful in architecture, and multi-yarn structures that allow for colorwork and soft actuation,” says Jenny Lin, the paper’s lead author and PhD student at Carnegie Mellon in the lab of James McCann, assistant professor of robotics at Carnegie Mellon and another author of the work.

She adds, “This is important, because as we develop more nuanced systems for generating more complicated knitting machine programs, we can now always answer the question of whether two machine knit objects — the object you want and the object your program makes — are truly the same.”

As a proof of concept, the team has implemented a foundational computational tool for applying program rewrites that preserve knit program meaning. This approach could be expanded for characterizing machine knitting to hand knitting, which is both more flexible and variable as a fabrication technique.

The team behind “fenced tangles” also includes Vidya Narayanan, applied scientist at Amazon who was advised by James McCann at Carnegie, Yuka Ikarashi, PhD candidate at MIT Computer Science & Artificial Intelligence Laboratory, Jonathan Ragan-Kelley of MIT Computer Science & Artificial Intelligence Laboratory, and Gilbert Bernstein, assistant professor of computer science and engineering at University of Washington, and they will present their work at SIGGRAPH 2023. The paper and team page can be found here.

Linked and Characterized

Medieval chainmail armor, small metal rings linked together in a pattern to form a mesh, have been used for thousands of years as protective gear for soldiers in battle. Picture a knight in their metal “suit” wearing chainmail armor as an additional layer of protection. Fast forward to the wide landscape of materials and fabrics in the modern era and chainmail-like materials remain a physical structure that is challenging to computationally represent, accounting for all of its unique mechanical properties. An international team of researchers from ETH Zürich in Switzerland and Université de Montréal in Canada draws inspiration from medieval chainmail armor, generalizing it to the concept of discrete interlocking materials, or DIM.

“These materials possess remarkable flexibility, allowing them to adapt to necessary shapes, while also demonstrating impressive strength beyond a certain range of deformation,” says Pengbin Tang, the lead author of the research and PhD student advised by Bernhard Thomaszewski, a senior scientist at ETH Zürich and adjunct professor at the Université de Montréal.

“These unique properties make DIM attractive in robotics, orthotics, sportswear and many other areas of application,” adds Stelian Coros, collaborator and head of the computational robotics lab (CRL) at ETH Zürich.