Inkbit Newsletter Series

Simplifying Latticing and Multi-Material Design

- March 31, 2025

- News

- 5 minutes

Welcome to the first edition of Inkbit’s newsletter series, where we explore advancements in additive manufacturing and how our technology is transforming design and production processes.

In this issue, we will focus on latticing and multi-material design, two techniques that offer significant advantages in product performance, weight reduction and customization. Designing and manufacturing parts like this can be difficult and time consuming, require multiple tools, manual assembly, and design workarounds. But with Inkbit’s Vision-Controlled Jetting (VCJ) technology, integrating multiple materials and lattice structures into a single, seamless part is now faster and easier.

In this issue, you’ll discover:

- How VCJ simplifies multi-material printing and eliminates post-production assembly.

- A real-world example showcasing a headphone ear cup printed using different materials and lattice structures.

- Design strategies for integrating materials using automatic and manual interlocking methods.

- How to get started with Inkbit by sending us your designs or requesting a reference lattice part.

Let’s dive in and see how Inkbit is making advanced design and manufacturing simpler than ever before!

Multi-Material Integration with VCJ Technology

Inkbit’s Vision-Controlled Jetting (VCJ) technology allows engineers to print multiple materials into a single part without the need for post-production assembly. By enabling both chemical bonding and mechanical interlocking, VCJ simplifies complex designs, reduces production time, and improves overall part performance.

Some key benefits of VCJ technology include:

- Ability to print multiple materials together without compromising strength or durability.

- Combine rigid, flexible, and lattice structures in a single build for greater design freedom.

- Speed up production by eliminating manual assembly.

Curious to see the results? Simply send us a multibodied STEP file with solid bodies assigned to different materials and lattices—we’ll take care of the rest. Not sure which lattice to use? Email us at [email protected] to request a lattice reference part.

Application Example: Multi-Material Headphone Ear Cup

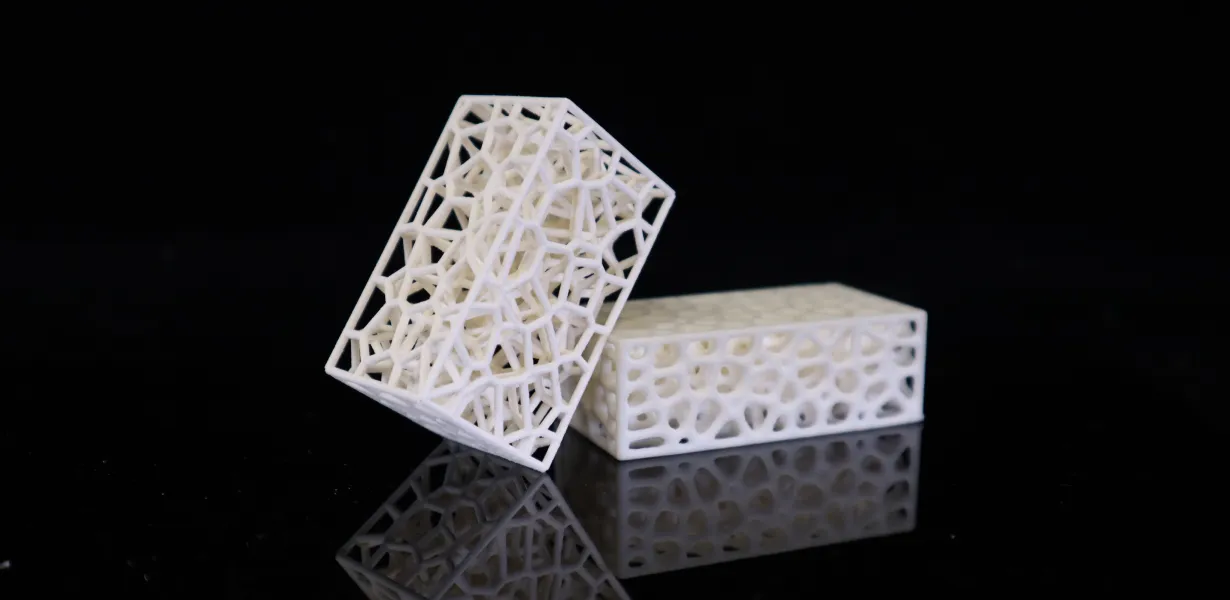

This headphone ear cup, printed using Inkbit’s VCJ technology, demonstrates how different materials can be seamlessly combined into a single part:

- Cross-Section View: The internal lattice structure provides cushioning while maintaining durability. The lattice design optimizes material usage while ensuring structural integrity.

- Full Printed Part: Different materials are printed together to form a functional part without requiring post-processing or assembly.

Multi-Material Integration: Automatic & Manual Interlocking

Inkbit’s Multi-Material Design Guide outlines two key strategies for securely integrating different materials within a single print:

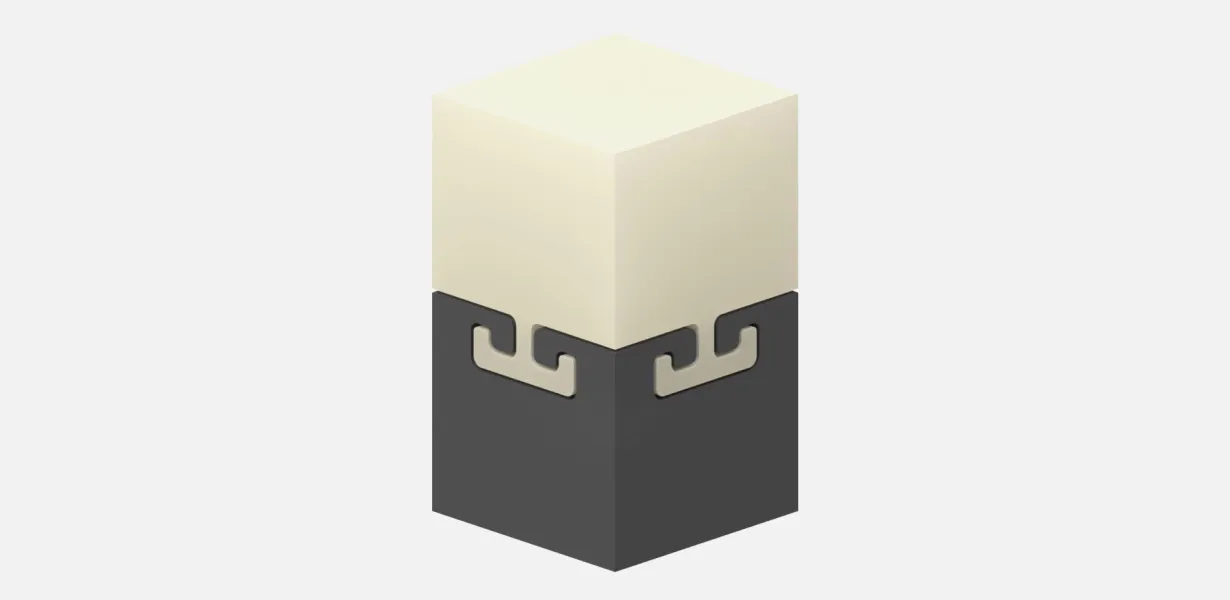

Automatic Interlock Design (AID)

- Applies predefined interlocking surface features to chemically incompatible materials, enabling secure mechanical connections.

- Simplifies the design process while ensuring materials remain securely attached.

- Ideal for applications where standard interlocking patterns are effective.

Manual Interlock Design (MID)

- Recommended for complex geometries or small contact areas where AID may not be sufficient.

- Allows for custom interlocking features tailored to specific design constraints.

- Ensures optimal adhesion and mechanical strength when automatic interlocks are not feasible.

The Future of Multi-Material Design and Latticing

As additive manufacturing continues to evolve, the ability to combine multiple materials and lattice structures within a single part is becoming increasingly important. With its precise control over material deposition and seamless integration of rigid, flexible, and lattice materials, Inkbit offers unparalleled design freedom and performance.

By combining advanced materials with automated design processes, Inkbit is making it easier than ever to create innovative products that meet the demands of modern engineering.

Get Started with Inkbit

Ready to see what Inkbit can do for you? Getting started is simple:

- Send us your design. Simply submit a multibodied STEP file with solid bodies assigned to different materials and lattices to [email protected].

- Not sure which lattice to choose? Request a reference part. Email us at [email protected] to request a reference part.

- Download our Design Guide for best practices and design strategies.

For any questions, reach out to [email protected]. We’re always happy to help!